The diameter of the sensor wires determines the upper most operating temperature. The larger the diameter, the higher the temperature rating. Choose alloy 600 over 304 SS or 316 SS when higher temperatures are expected. The environment is another critical factor when determining the best material.

| Illustrations (X-Ray) | Junction Type | Application Notes |

|---|---|---|

|

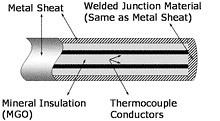

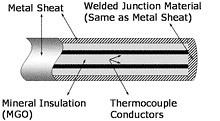

Grounded Junction | The sheath and conductors are welded together, forming a completely sealed integral junction.Recommended in the presence of liquids, moisture, gas or high pressure.The wire is protected from corrosive or erosive conditions. Response time with this style approaches that of the exposed junction. |

|

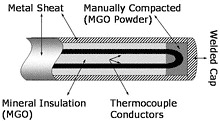

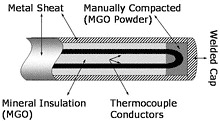

Ungrounded Junction | On this type the thermocouple junction is fully insulated from the welded sheath end. The ungrounded junction is excellent for applications where stray EMFs would affect the reading and for frequent or rapid temperature cycling. Response time is longer than for the grounded junction. |

|

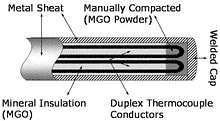

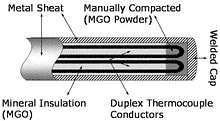

Dual Ungrounded Junction | Two separate thermocouples are encased in a single sheath. The isolation would prevent ground loop errors if wired to separate instruments. Only available as ungrounded junctions. |

|

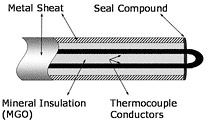

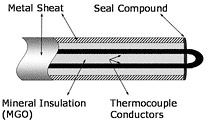

Exposed Junction | Thermocouple wires are butt welded, and insulation is sealed against liquid or gas penetration. This junction style provides the fastest possible response time but leaves the thermocouple wires unprotected against corrosive or mechanical damage. |

The diameter of the sensor wires determines the upper most operating temperature. The larger the diameter, the higher the temperature rating. Choose alloy 600 over 304 SS or 316 SS when higher temperatures are expected. The environment is another critical factor when determining the best material.

| Illustrations (X-Ray) | Junction Type | Application Notes |

|---|---|---|

|

Grounded Junction | The sheath and conductors are welded together, forming a completely sealed integral junction.Recommended in the presence of liquids, moisture, gas or high pressure.The wire is protected from corrosive or erosive conditions. Response time with this style approaches that of the exposed junction. |

|

Ungrounded Junction | On this type the thermocouple junction is fully insulated from the welded sheath end. The ungrounded junction is excellent for applications where stray EMFs would affect the reading and for frequent or rapid temperature cycling. Response time is longer than for the grounded junction. |

|

Dual Ungrounded Junction | Two separate thermocouples are encased in a single sheath. The isolation would prevent ground loop errors if wired to separate instruments. Only available as ungrounded junctions. |

|

Exposed Junction | Thermocouple wires are butt welded, and insulation is sealed against liquid or gas penetration. This junction style provides the fastest possible response time but leaves the thermocouple wires unprotected against corrosive or mechanical damage. |