The smaller the diameter, the faster the thermocouple will respond. Grounding the junction will also improve the response time by approximately 50 percent. This is based on the sensor achieving 63.2 percent of the final reading, or to the first time constant. It will take about five time constants to obtain steady state readings. Since you are actually interested in the temperature of the surrounding medium, accuracy depends on the ability of the sensor to conduct heat from its outer sheath to the element wire.

Several factors come into play:

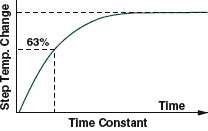

The most commonly noted is “time constant” (thermal response time). Time constant, or thermal response time, is an expression of how quickly a sensor responds to temperature changes. As expressed here, time response is defined as how long it takes a sensor to reach 63.2 percent of a step temperature change.

Response is a function of the mass of the sensor and its efficiency in transferring heat from its outer surfaces to the wire sensing element. A rapid time response is essential for accuracy in a system with sharp temperature changes.

Time response varies with the probe’s physical size and design.

| Average Response Time Still Water (seconds) | |||

|---|---|---|---|

| Readings are to 63.2% of measured temperature. | |||

| Sheath Diameter | Grounded Junction | Ungrounded Junction | |

| 1/2 | 0,500 | 15 | 20 |

| 3/8 | 0,375 | 8 | 11 |

| 5/16 | 0,313 | 5 | 7 |

| 1/4 | 0,250 | 2,2 | 4,1 |

| 3/16 | 0,188 | 1 | 2,3 |

| 1/8 | 0,125 | 0,5 | 1,1 |

| 1/16 | 0,062 | 0,22 | 0,4 |

| 1/25 | 0,040 | 0,04 | 0,13 |

| Temperature Response Time Of Still Water At 80 Celcius Measured with a Thermocouple having a .250″ Sheat Diameter. |

||||

|---|---|---|---|---|

| Time Constant | Response Time | Step Change | Measured Temperature | |

| Grounded | Ungrounded | |||

| 1 | 2,2 | 4,1 | 63,2% | 50,6 |

| 2 | 4,4 | 8,2 | 86,5% | 69,2 |

| 3 | 6,6 | 12,3 | 95,0% | 76,0 |

| 4 | 8,8 | 16,4 | 98,2% | 78,6 |

| 5 | 11,0 | 20,5 | 99,3% | 79,4 |

| 6 | 13,2 | 24,6 | 99,8% | 79,8 |

|

||||

The smaller the diameter, the faster the thermocouple will respond. Grounding the junction will also improve the response time by approximately 50 percent. This is based on the sensor achieving 63.2 percent of the final reading, or to the first time constant. It will take about five time constants to obtain steady state readings. Since you are actually interested in the temperature of the surrounding medium, accuracy depends on the ability of the sensor to conduct heat from its outer sheath to the element wire.

Several factors come into play:

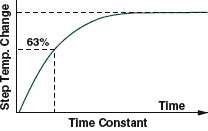

The most commonly noted is “time constant” (thermal response time). Time constant, or thermal response time, is an expression of how quickly a sensor responds to temperature changes. As expressed here, time response is defined as how long it takes a sensor to reach 63.2 percent of a step temperature change.

Response is a function of the mass of the sensor and its efficiency in transferring heat from its outer surfaces to the wire sensing element. A rapid time response is essential for accuracy in a system with sharp temperature changes.

Time response varies with the probe’s physical size and design.

| Average Response Time Still Water (seconds) | |||

|---|---|---|---|

| Readings are to 63.2% of measured temperature. | |||

| Sheath Diameter | Grounded Junction | Ungrounded Junction | |

| 1/2 | 0,500 | 15 | 20 |

| 3/8 | 0,375 | 8 | 11 |

| 5/16 | 0,313 | 5 | 7 |

| 1/4 | 0,250 | 2,2 | 4,1 |

| 3/16 | 0,188 | 1 | 2,3 |

| 1/8 | 0,125 | 0,5 | 1,1 |

| 1/16 | 0,062 | 0,22 | 0,4 |

| 1/25 | 0,040 | 0,04 | 0,13 |

| Temperature Response Time Of Still Water At 80 Celcius Measured with a Thermocouple having a .250″ Sheat Diameter. |

||||

|---|---|---|---|---|

| Time Constant | Response Time | Step Change | Measured Temperature | |

| Grounded | Ungrounded | |||

| 1 | 2,2 | 4,1 | 63,2% | 50,6 |

| 2 | 4,4 | 8,2 | 86,5% | 69,2 |

| 3 | 6,6 | 12,3 | 95,0% | 76,0 |

| 4 | 8,8 | 16,4 | 98,2% | 78,6 |

| 5 | 11,0 | 20,5 | 99,3% | 79,4 |

| 6 | 13,2 | 24,6 | 99,8% | 79,8 |

|

||||