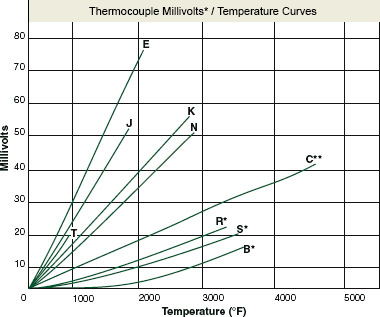

Thermocouples are classified by calibration type because they have differing EMF (electromotive force) versus temperature curves. Some generate considerably more voltage at lower temperatures, while others do not begin to develop a significant voltage until subjected to high temperatures.

Also, calibration types are designed to deliver as close to a straight line voltage curve inside their temperature application range as possible. This makes it easier for an instrument or temperature controller to correctly correlate the received voltage to a particular temperature.

Additionally, thermocouple calibration types have different levels of compatibility with different atmospheres. Chemical reaction between certain thermocouple alloys and the application atmosphere could cause metallurgy degradation, making another calibration type more suitable for sensor life and accuracy requirements.

| ASTM E-230 Letter |

Thermoelement Alloys |

Minimum & Maximum Temperatue Range | |

|---|---|---|---|

| °C | °F | ||

| B | 870 to 1700 | 1600 to 3100 | |

| BP (+) | Pt 30% Rh | ||

| BN (-) | Pt 6% Rh | ||

| E | -200 to 870 | -328 to 1600 | |

| EP (+) | Chromel | ||

| EN (-) | Constantan | ||

| J | 0 to 760 | 32 to 1400 | |

| JP (+) | Iron | ||

| JN (-) | Constantan | ||

| K | -200 to 1260 | -328 to 2300 | |

| KP (+) | Chromel | ||

| KN (-) | Alumel | ||

| N | 0 to 1260 | 32 to 2300 | |

| NP (+) | Nicrosil | ||

| NN (-) | Nisil | ||

| R | 0 to 1480 | 32 to 2700 | |

| RP (+) | Pt 13% Rh | ||

| RN (-) | Pure Pt | ||

| S | 0 to 1480 | 32 to 2700 | |

| SP (+) | Pt 10% Rh | ||

| SN (-) | Pure Pt | ||

| T | -200 to 370 | -328 to 700 | |

| TP (+) | Copper | ||

| TN (-) | Constantan | ||

Thermocouple Types

Calibration types have been established by the American Society for Testing and Materials (ASTM) according to their temperature versus EMF characteristics in accordance with ITS-90, in standard or special tolerances.

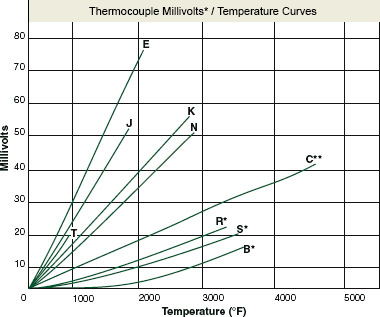

Thermocouples are classified by calibration type because they have differing EMF (electromotive force) versus temperature curves. Some generate considerably more voltage at lower temperatures, while others do not begin to develop a significant voltage until subjected to high temperatures.

Also, calibration types are designed to deliver as close to a straight line voltage curve inside their temperature application range as possible. This makes it easier for an instrument or temperature controller to correctly correlate the received voltage to a particular temperature.

Additionally, thermocouple calibration types have different levels of compatibility with different atmospheres. Chemical reaction between certain thermocouple alloys and the application atmosphere could cause metallurgy degradation, making another calibration type more suitable for sensor life and accuracy requirements.

| ASTM E-230 Letter |

Thermoelement Alloys |

Minimum & Maximum Temperatue Range | |

|---|---|---|---|

| °C | °F | ||

| B | 870 to 1700 | 1600 to 3100 | |

| BP (+) | Pt 30% Rh | ||

| BN (-) | Pt 6% Rh | ||

| E | -200 to 870 | -328 to 1600 | |

| EP (+) | Chromel | ||

| EN (-) | Constantan | ||

| J | 0 to 760 | 32 to 1400 | |

| JP (+) | Iron | ||

| JN (-) | Constantan | ||

| K | -200 to 1260 | -328 to 2300 | |

| KP (+) | Chromel | ||

| KN (-) | Alumel | ||

| N | 0 to 1260 | 32 to 2300 | |

| NP (+) | Nicrosil | ||

| NN (-) | Nisil | ||

| R | 0 to 1480 | 32 to 2700 | |

| RP (+) | Pt 13% Rh | ||

| RN (-) | Pure Pt | ||

| S | 0 to 1480 | 32 to 2700 | |

| SP (+) | Pt 10% Rh | ||

| SN (-) | Pure Pt | ||

| T | -200 to 370 | -328 to 700 | |

| TP (+) | Copper | ||

| TN (-) | Constantan | ||

Thermocouple Types

Calibration types have been established by the American Society for Testing and Materials (ASTM) according to their temperature versus EMF characteristics in accordance with ITS-90, in standard or special tolerances.