When Thermocouples or RTD’s or any other sensors are exposed to harsh atmospheres they are damaged. This damaged due to mechanical abused or chemical contamination can be avoided by the use of protection tubes or Thermowells.

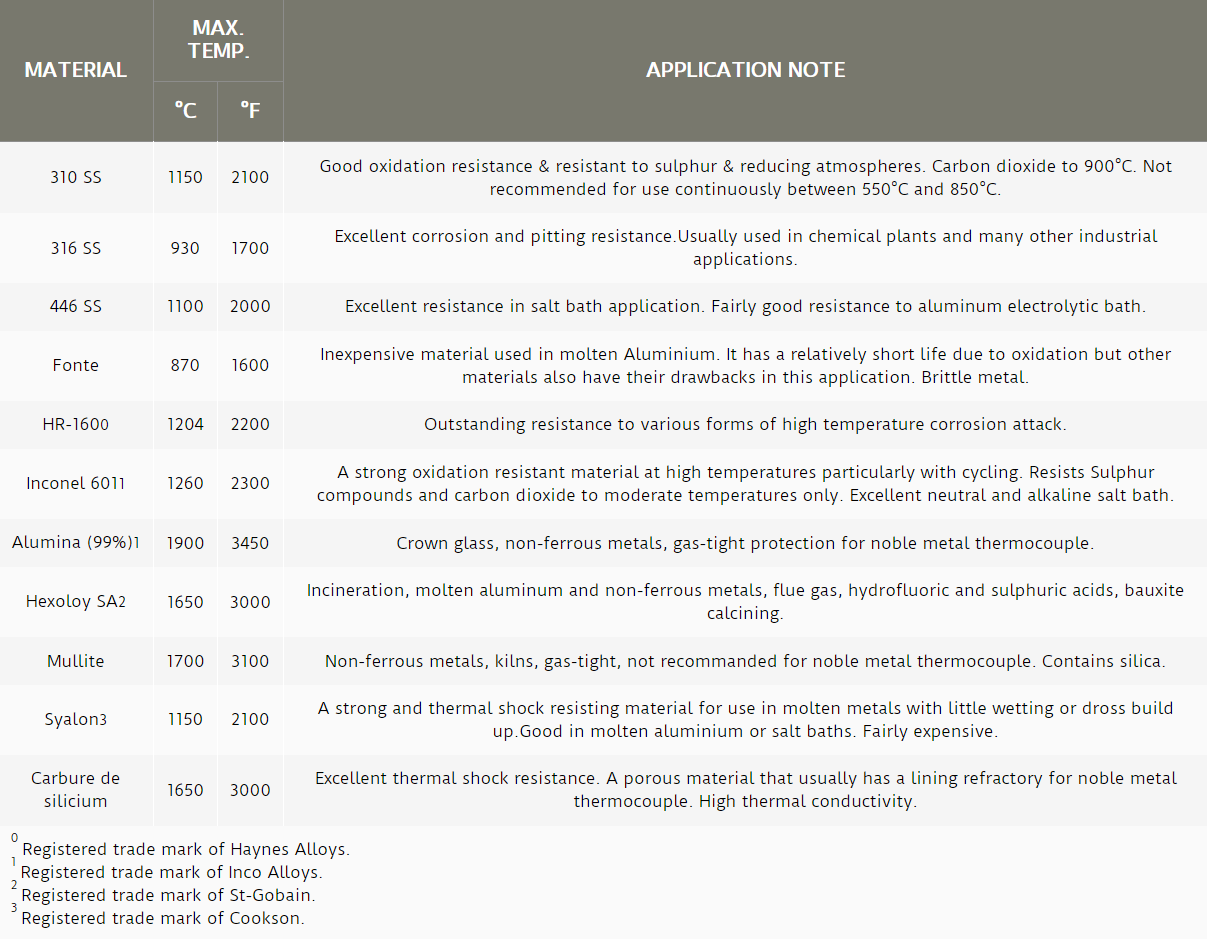

Thermowells and Protection Tubes are closed at one end, normally the harsh environment or process end, and opened at the termination end, various methods are used to assemble the tube, sensor, and connection head with termination into the process. Depending on the chemical or mechanical environment to which the Sensor will be subjected the material for the protection tube is selected. The table below shows the most popular.

Thermowells

Thermowells

Metal or Ceramic Protection Tube

| Material | Max. Temp. |

Application Note | |

|---|---|---|---|

| °C | °F | ||

| 310 SS | 1150 | 2100 | Good oxidation resistance & resistant to sulphur & reducing atmospheres. Carbon dioxide to 900°C. Not recommended for use continuously between 550°C and 850°C. |

| 316 SS | 930 | 1700 | Excellent corrosion and pitting resistance.Usually used in chemical plants and many other industrial applications. |

| 446 SS | 1100 | 2000 | Excellent resistance in salt bath application. Fairly good resistance to aluminum electrolytic bath. |

| Fonte | 870 | 1600 | Inexpensive material used in molten Aluminium. It has a relatively short life due to oxidation but other materials also have their drawbacks in this application. Brittle metal. |

| HR-1600 | 1204 | 2200 | Outstanding resistance to various forms of high temperature corrosion attack. |

| Inconel 6011 | 1260 | 2300 | A strong oxidation resistant material at high temperatures particularly with cycling. Resists Sulphur compounds and carbon dioxide to moderate temperatures only. Excellent neutral and alkaline salt bath. |

| Alumina (99%)1 | 1900 | 3450 | Crown glass, non-ferrous metals, gas-tight protection for noble metal thermocouple. |

| Hexoloy SA2 | 1650 | 3000 | Incineration, molten aluminum and non-ferrous metals, flue gas, hydrofluoric and sulphuric acids, bauxite calcining. |

| Mullite | 1700 | 3100 | Non-ferrous metals, kilns, gas-tight, not recommanded for noble metal thermocouple. Contains silica. |

| Syalon3 | 1150 | 2100 | A strong and thermal shock resisting material for use in molten metals with little wetting or dross build up.Good in molten aluminium or salt baths. Fairly expensive. |

| Carbure de silicium | 1650 | 3000 | Excellent thermal shock resistance. A porous material that usually has a lining refractory for noble metal thermocouple. High thermal conductivity. |

| 0 Registered trade mark of Haynes Alloys. 1 Registered trade mark of Inco Alloys. 2 Registered trade mark of St-Gobain. 3 Registered trade mark of Cookson. |

|||