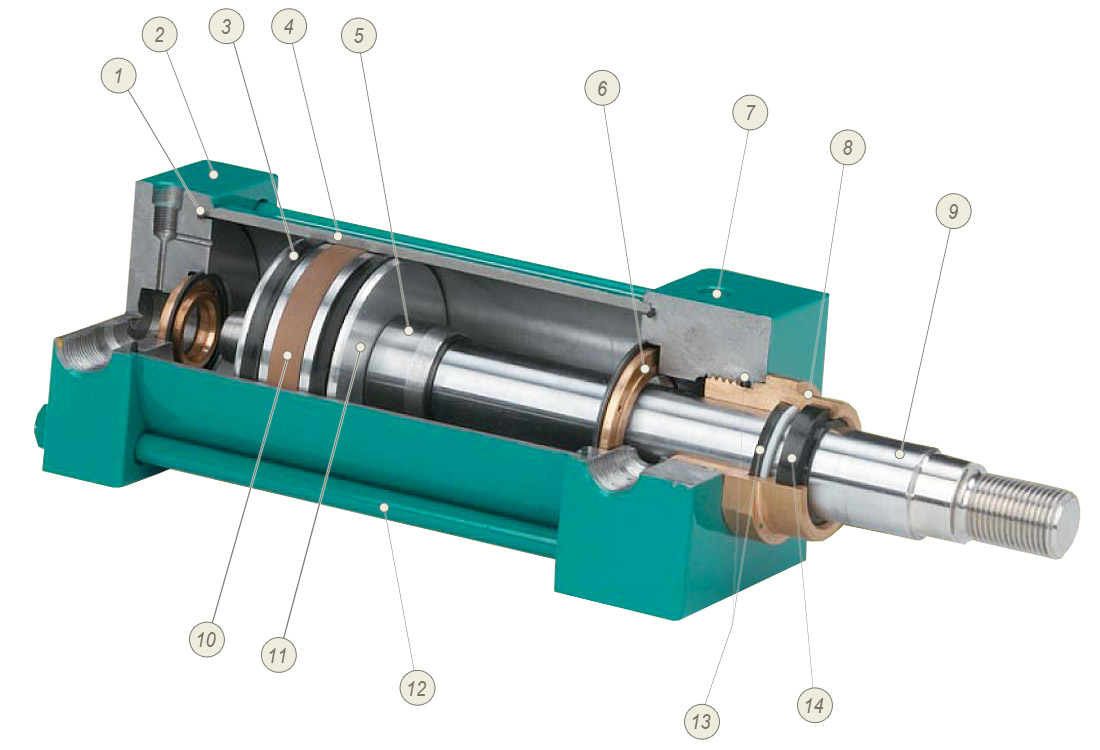

HL Series

Medium Pressure Hydraulic Cylinder

1½” – 14″ Bore

1½” – 14″ Bore

The materials used to manufacture RDC CONTROL LTD cylinders are selected from the best quality available. The HL Series components are manufactured with the latest sophisticated precision equipment. Each cylinder is assembled and individually tested under strict quality conditions.

Integrated Cushion Seal Ring

The cylinder cushion seals are offered as optional equipment. They consist of a double action floating cushion ring which eliminates any potential alignment problems and the need of a mechanical check valve that would require constant maintenance.

This double action cushion ring diverts the oil through the adjustable orifice only for smoother end of stroke cushioning.

On the return stroke, the cushion seal allows oil to pass behind the piston thus obtaining a rapid breakaway and increase cycle rate.

The cushion adjustment screws supplied by RDC Contrôle Ltée are specially designed with extra fine threads (UNEF) to obtain a perfect adjustment. For added security, the screws will leak fluid before being accidentally ejected if they are attempted to be removed under pressure. These screws are normally installed on side n°2 of the cylinder except for trunnion mountings (T1, T2 and T4) on which they can be found on side n°3.

Standard Piston Wear Strip

All standard pistons on HL Series cylinders are equipped with a bronze and glass impregnated teflon wear band. In addition to giving the piston a more secure fit, the self-lubricating feature protects the interior surface and adds to the life of the cylinder.

Cartridge Type Gland Bushing

The gland bushing of the HL Series cylinders is designed for easy removal, thus allowing easy seal maintenance without dismantling the entire cylinder. For piston rod diameters less than or equal to 1 3/4, a simple wrench may be used.

For piston rod diameters greater than 1 3/4, the non-threaded gland bushing is held in place with a removable bolted-on plate.